The rigours of software-defined vehicle development require a new standard in design and systems engineering, simulation, and connectivity

Software-defined vehicles (SDVs) are transforming the automotive industry from a hardware-centric world into a software-driven mobility ecosystem. Consequently, approaches to product design and systems engineering are changing.

“In the past, development cycles were paced by long hardware validation loops,” says Guillaume Belloncle, CATIA MBSE Technical Expert Director at Dassault Systèmes (DS). “Today, hardware remains in the field for more than a decade while software can be updated every few weeks. This requires a completely new engineering discipline, where hardware and software are conceived together rather than in isolation.”

Adopting a system-level method is particularly important as functions like automated driving are brought to market: a small tweak to perception or control software could affect sensors, electrical networks, energy consumption, braking performance and overall safety. Meanwhile, automotive companies are expanding beyond traditional vehicle manufacturing and into mobility services, charging networks, digital ecosystems and more. In this expanded arena, Belloncle tells Automotive World that new tools will be necessary to analyse user needs, coordinate multiple technologies, integrate partners, and comply with increasingly demanding global regulations.

A new way of working

SDVs present several structural challenges that affect every aspect of development. Automakers are shifting from distributed ECUs to centralised and zonal E/E architectures that can support frequent over-the-air updates and independent software lifecycles. “This creates strong interdependencies and requires much tighter coordination than traditional V-cycle workflows,” explains Belloncle.

Modern vehicles must also meet stringent standards—including ISO 26262 for functional safety, ISO 21434 for cyber security, UN156 for software update management, and Automotive Software Process Improvement and Capability Determination (ASPICE). “These standards require clear traceability, controlled integration and robust validation, and they must be taken into consideration from the very beginning of a new programme,” he adds. However, maintenance can be difficult when functions and impacted engineering artefacts evolve continuously after a vehicle is launched.

To ensure a high standard of performance, user experience and safety, an SDV requires digital continuity through each development step: architecture, model-based design, simulation, test and in-service fleet data. Success could mean that organisations need to adapt: “The rigour required for safety in SDVs demands more agile development, continuous integration, and real-time collaboration between OEMs, Tier 1s and software and technology partners.”

Imagine, then test

As brand differentiation shifts away from basic performance and towards in-vehicle amenities, the user experience becomes vital, and SDVs can provide customers a sense of improvement over time. “This paves the way for new business models such as pay-per-use features, subscription services and mobility-as-a-service fleets,” says Belloncle.

Before these can be implemented, however, automakers need to imagine and test them long before the necessary hardware has been created. To enable this, DS offers an end-to-end development environment through its 3DExperience platform, which supports engineers and ensures that entire vehicle systems—from concept to in-service operation—remain consistent and traceable.

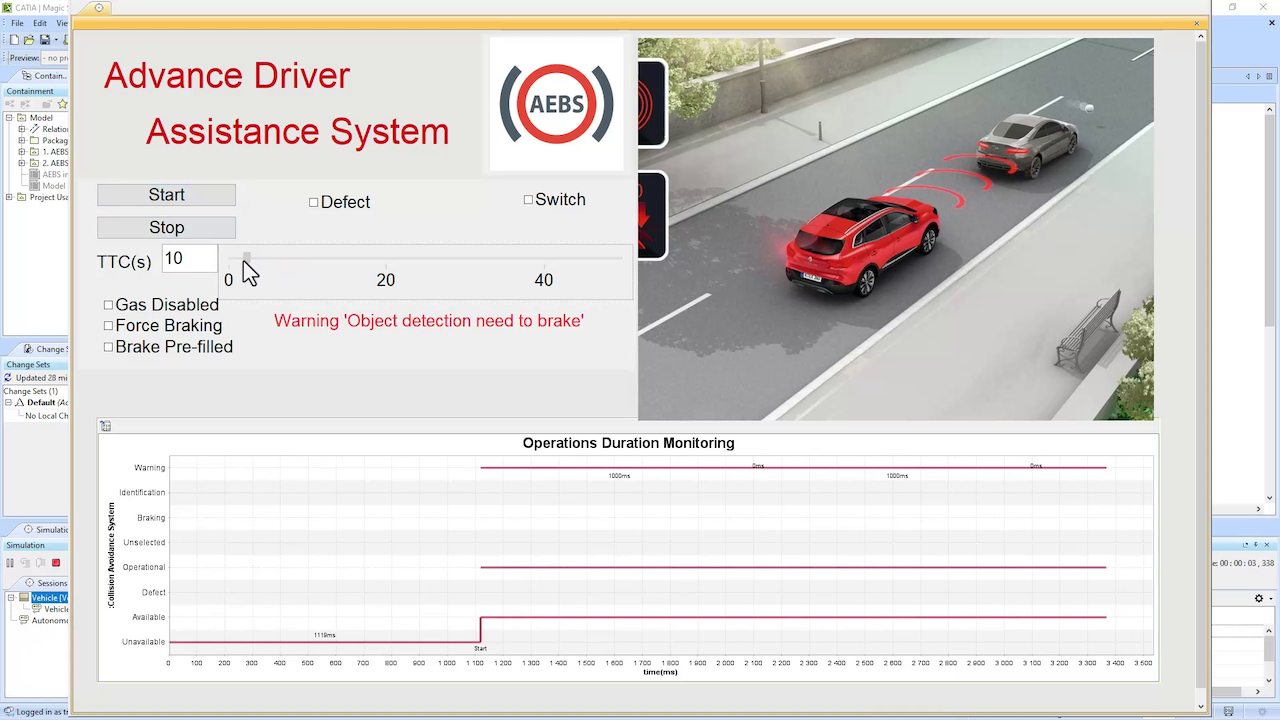

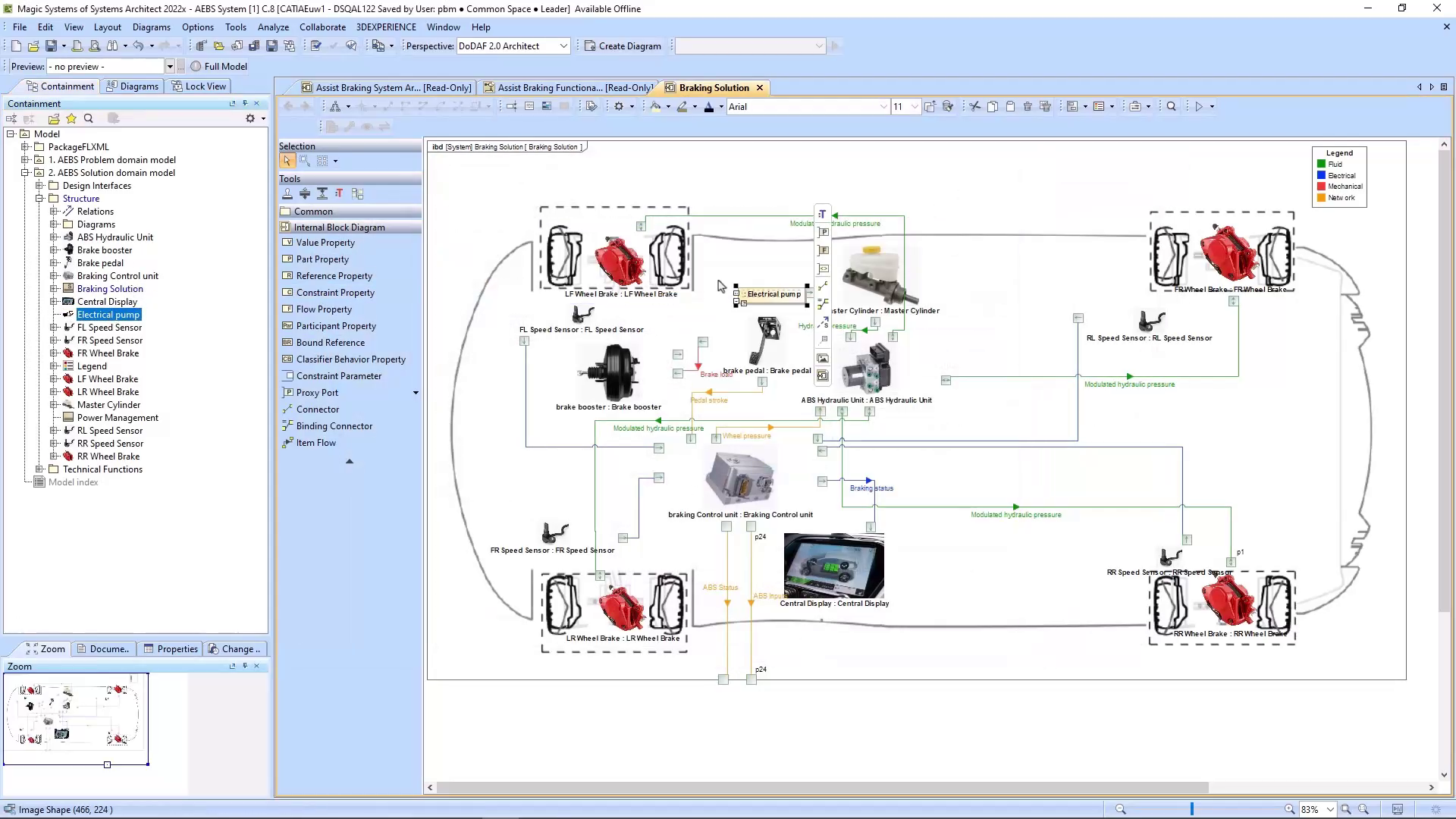

Model-Based Systems Engineering (MBSE), supported by CATIA Magic and based on 3DExperience, allows teams to capture stakeholder needs, build conceptual and solutions architectures, and simulate behaviour to evaluate trade-offs early, leveraging industrial standard systems modelling language. This includes E/E architecture design—essential as OEMs develop their new vehicle platforms.

With CATIA Stimulus, ‘requirement-in-the-loop’ simulation can detect ambiguous, inconsistent or missing requirements before moving into design or coding.

Through digital continuity, systems architecture models guide electrical, electronics, software and mechanical engineers to improve productivity, reduce the risk of implementation errors and ensure the final design reflects initial specifications.

[SDVs pave] the way for new business models such as pay-per-use features, subscription services and mobility-as-a-service fleets

“Safety and cyber security constraints are embedded throughout the process,” emphasises Belloncle. “Hazard analysis, failure mode and effects analysis, threat assessment and remediation analysis, and compliance with ISO 26262 and ISO 21434 can be performed directly in context of the system models, helping to prevent last-minute corrections and keeping personalised features safe and secure.”

A fully connected ecosystem

Advanced in-vehicle technology requires next-gen development tools to deliver it. High-speed connectivity provided by 5G offers the bandwidth and low latency required for continuous communication between a vehicle, the cloud and its surroundings. When combined with a virtual twin of the vehicle, this allows real-time monitoring, predictive maintenance, adaptive software updates and learning from fleet-level intelligence.

Using a virtual twin approach, Belloncle states that all engineering disciplines can work together on DS’ 3DExperience platform using shared and consistent data. This ensures proper traceability of decisions, controlled version management, hardware and software integration, and coordinated reviews throughout the vehicle’s development lifecycle. OEMs have a unified environment to design and validate user-centred, software-driven features, and check that the experiences delivered to drivers and passengers are consistent, safe and secured throughout the vehicle’s lifecycle.

Belloncle highlights the ‘Vision 4Rescue’ project from Software République—an open innovation ecosystem consisting of Atos, DS, JCDecaux, Orange, Renault Group, STMicroelectronics, and Thales—as a strong illustration. “[The project] connected vehicles, drones, urban furniture and emergency command systems to support faster and better-coordinated rescue missions.”

DS contributed the virtual twin and system-of-systems simulation needed to model every aspect of the mission, from early risk analysis to real-time coordination. “This helped demonstrate how a fully connected ecosystem can reduce intervention time, which in emergency services directly translates to saving lives,” he says.

Exploring thousands of ‘what ifs’

Both now and in the future, Belloncle considers virtual development to be essential for bringing SDV concepts to reality. While it does not eliminate physical validation, virtual testing can significantly reduce prototyping and improve confidence before real-world trials.

“Virtual development has become essential for SDVs because it allows teams to explore ideas, test safety and validate software long before building hardware. Engineers can use virtual twins to evaluate design choices, run safety analyses, assess energy consumption, test software updates or explore thousands of ‘what-if’ scenarios.”

This is particularly important for automated driving systems, where real-world testing alone is far too slow, risky or costly. With a solution like DS’ CATIA Scaner, engineers can run model-in-the-loop, software-in-the-loop, hardware-in-the-loop, and driver-in-the-loop tests within realistic environments. Renault is one automaker already using this approach to validate virtual twins of its vehicles and run millions of simulated kilometers during each development phase.

“Among the 20 major automotive groups, 16 design their vehicles with CATIA; we are already central to global vehicle development,” claims Belloncle. What’s clear is that the shift to SDVs requires collaborative environments as flexible and scalable as the products themselves. With more than 40 years of close collaboration with automakers, suppliers and other industry stakeholders, DS believes it will now help create the in-vehicle experiences that accelerate the emergence of a new era.